Advantages

step1

Material Preparation

The primary materials for filter cartridges include filter media, support materials, and housing materials. Prior to production, these materials require pre-treatment processes such as screening, cleaning, and drying.

step2

Material Mixing

Mix the filter media, support material, and shell material together in a specific ratio to form the composite material.

step3

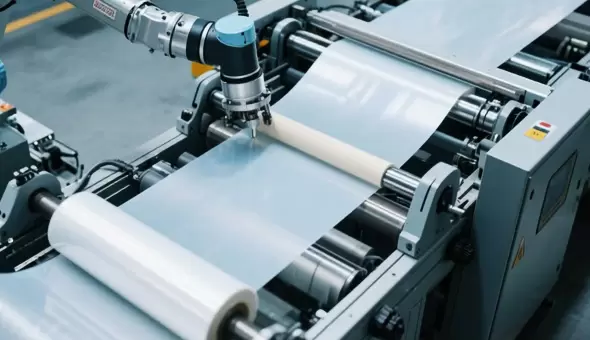

Extrusion molding

The mixture is extruded through an extruder to form the inner core of the filter element.

step4

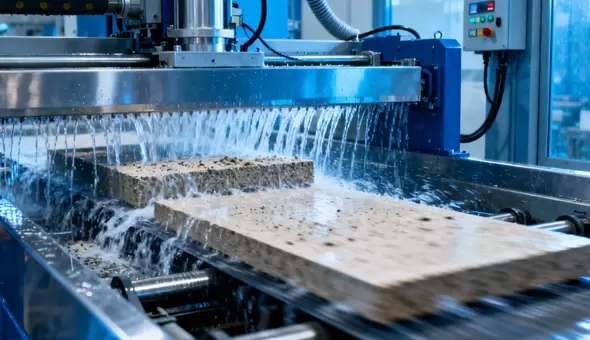

Heat forming

Place the inner core and outer shell materials of the filter element into the heat sealing machine, where they are thermally bonded and formed under high temperature and pressure.

step5

Cutting

Cut the thermoformed filter element to the appropriate length for use.

step6

Inspection Packaging

Inspect and package the cut filter elements, then transfer them to the finished goods warehouse.

OVERVIEW

01

Global Joint Research and Development

We collaborate with leading international enterprises and research institutions such as Japan's Bi Chemical Co., Ltd., France's Veolia, and South Korea's LG Chem to jointly advance the innovative R&D of high-performance separation materials and cutting-edge membrane technologies. By integrating global intellectual resources, we have established a collaborative R&D system with international competitiveness, ensuring our technologies remain at the forefront of the industry.

OVERVIEW

02

Closed-Loop System Integration

We provide end-to-end closed-loop solutions spanning material R&D, equipment manufacturing, and process design. Leveraging deep expertise in salt-water separation and resource recovery applications, we significantly enhance resource utilization and energy efficiency, delivering green engineering models that combine low emissions, low operating costs, and high recovery rates for our clients.

OVERVIEW

03

Highland Manufacturing System

Leveraging Xizang's unique geographical and climatic conditions, we have established a globally rare high-altitude smart manufacturing base. This has enabled breakthrough improvements in product corrosion resistance, mechanical strength, and stability. All products undergo extreme environment simulation testing and high-altitude field validation, ensuring exceptional performance under the world's most demanding operating conditions.