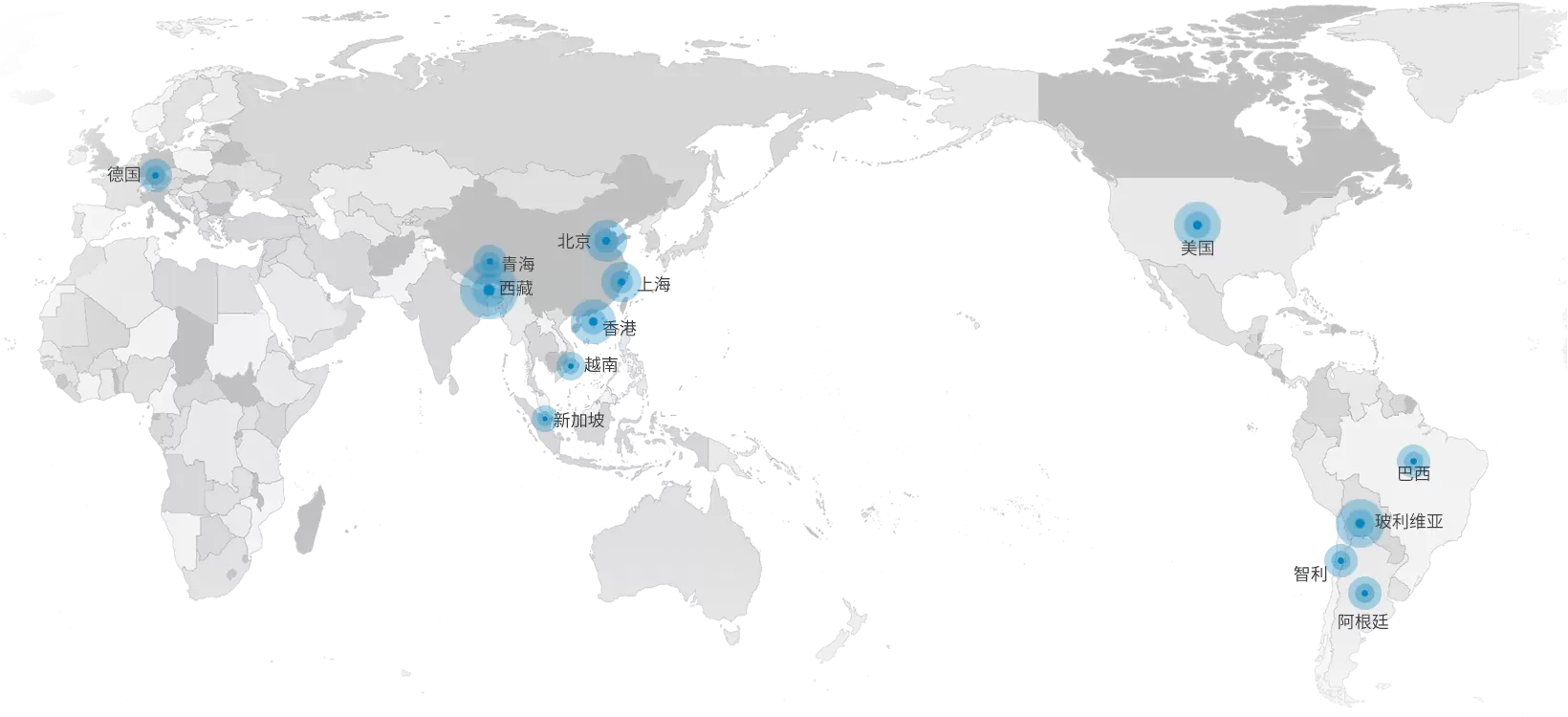

Xizang Jinyifeng Lithium Industry is a specialized equipment manufacturer in the field of lithium extraction from salt lakes, focusing on the development and production of filter membrane materials. We are committed to becoming a globally leading supplier of separation materials. Currently, our products and solutions are supplied to lithium carbonate production plants utilizing brine from salt lakes across South America, North America, and most regions of Qinghai and Xizang in China.

We provide specialized expertise encompassing R&D, new material production, and the development of customized industrial products tailored to meet industry demands, leveraging the unique composition of regional salt lake brines.

2023Year

Date of Establishment

6+

Product Categories

20+

Partner Companies

10+

Patent Certificate

Application Scenarios: Pre-treatment for lithium extraction processes, industrial wastewater purification, biopharmaceuticals, biochemical process isolation

Application Scenarios: Pre-treatment for lithium extraction processes, industrial wastewater purification, biopharmaceuticals, biochemical process isolation

Technical Features: Membrane pore size approximately 0.01–0.1μm, precise and stable

Technical Features: Membrane pore size approximately 0.01–0.1μm, precise and stable

High flux, strong anti-fouling capability, supports batch operation

High flux, strong anti-fouling capability, supports batch operation

Modular parallel installation for flexible adaptation to various operating conditions

Modular parallel installation for flexible adaptation to various operating conditions

Application Scenarios: Brine pre-filtration, membrane system front-end protection, extraction liquid clarification filtration, precision reaction liquid filtration

Application Scenarios: Brine pre-filtration, membrane system front-end protection, extraction liquid clarification filtration, precision reaction liquid filtration

Technical Features: Single cartridge flow rate up to 30–60 m³/h

Technical Features: Single cartridge flow rate up to 30–60 m³/h

Multiple precision grades available (1μm ~ 50μm)

Multiple precision grades available (1μm ~ 50μm)

Withstands pressures up to 3–5 bar, featuring easy installation and maintenance

Withstands pressures up to 3–5 bar, featuring easy installation and maintenance

Application Scenarios: Brine Refining, Seawater Desalination, Battery-Grade Water Preparation, Process Water Recirculation

Application Scenarios: Brine Refining, Seawater Desalination, Battery-Grade Water Preparation, Process Water Recirculation

Technical Features: Desalination rate exceeding 99.5%

Technical Features: Desalination rate exceeding 99.5%

Energy-efficient membrane type supports ultra-low pressure operation (ULP)

Energy-efficient membrane type supports ultra-low pressure operation (ULP)

Complementary anti-fouling membrane type adapts to complex water conditions

Complementary anti-fouling membrane type adapts to complex water conditions

Application Scenarios: Salt-water separation, brine pre-concentration, chemical recovery, pharmaceutical intermediate purification

Application Scenarios: Salt-water separation, brine pre-concentration, chemical recovery, pharmaceutical intermediate purification

Technical Features: Molecular weight retention range of 200–1000 Da

Technical Features: Molecular weight retention range of 200–1000 Da

High-throughput separation achievable at lower operating pressures

High-throughput separation achievable at lower operating pressures

High salt tolerance and strong contamination resistance, suitable for high-hardness water

High salt tolerance and strong contamination resistance, suitable for high-hardness water

Application Scenarios: Treatment of highly corrosive wastewater, filtration of organic solvents, removal of heavy metals, rare earth recovery, etc.

Application Scenarios: Treatment of highly corrosive wastewater, filtration of organic solvents, removal of heavy metals, rare earth recovery, etc.

Technical Features: Membrane pore sizes ranging from 0.01μm to 0.1μm, retaining particulate matter / colloids / microorganisms and other impurities

Technical Features: Membrane pore sizes ranging from 0.01μm to 0.1μm, retaining particulate matter / colloids / microorganisms and other impurities

Operating temperature up to 250°C

Operating temperature up to 250°C

Extended service life (>5 years), suitable for repeated CIP cleaning

Extended service life (>5 years), suitable for repeated CIP cleaning

Corporate Vision

Green manufacturing and low-carbon operations Reject pollution, reduce waste

Corporate Mission

It conveys the company's dedication to green separation technology, along with its sense of responsibility and mission toward a sustainable global future.

Corporate Values

We are committed to creating eco-friendly solutions that balance high performance with low emissions.

Corporate Objectives

Based in the Roof of the World—Xizang, China, serving global saltwater separation and green energy development

Integrity

Responsibility

Environmental Protection

Cleaning

Co-creation

Shared